Duchy College trial demonstrates the benefits of adding SlurryForSoil™ to slurry are carried through to silage.

Replicating and extending a trial first conducted back in 2021, Duchy College split one of its dairy herds into trial groups each with separate slurry lagoons in order to compare the effects of SlurryForSoil™ on grassland productivity.

Yield and nutrient analysis of forage harvested from grassland which had received slurry treated with SlurryForSoil™ was compared with grassland which had received slurry alone.

Teaming up with silage experts, BPI Agriculture, the manufacturer of SlurryForSoil™, Sylgen Animal Health, took the trial a step further and analysed resulting silage.

Stuart Anthony, Area Sales Manager, explained why BPI Agriculture choose to collaborate: “Our business is all about helping farmers get the most from their grass. With ever increasing financial and environmental pressures, it’s increasingly important to maximise the value of forage.

“SlurryForSoil is a very interesting product, with similar objectives – to improve the productive value of grassland while reducing the environmental impact of production.”

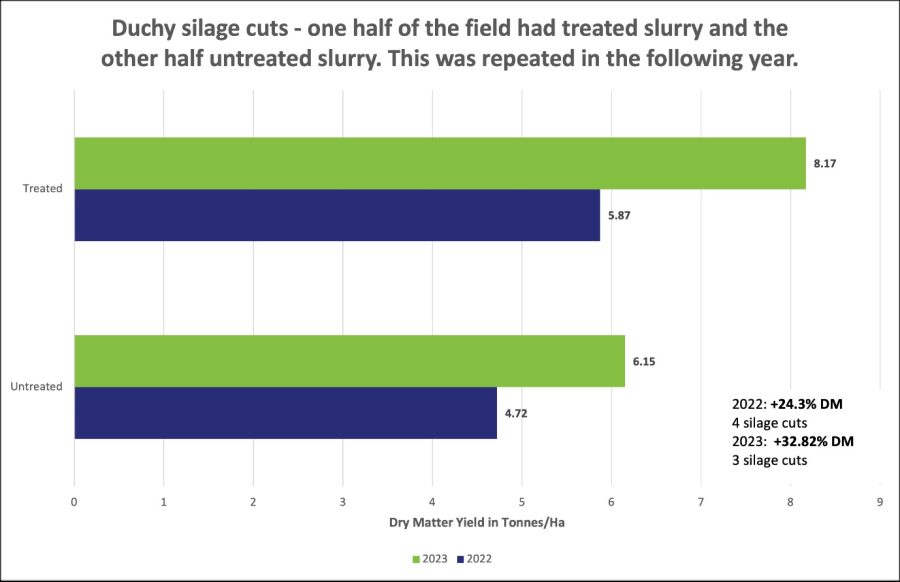

Results of the first phase of the trial – analysis of SlurryForSoil™’s impact on grass and then forage quality – once again demonstrated how the microbes improve quantity and quality.

“It was great to see SlurryForSoil™ enhance grass dry matter yields by over 30% – a result which is comparable with previous year’s trials and is very important for making good quality silage,” said Sylgen Animal Health Director, Romney Jackson. “Indicators showed an improvement in potential intake too with higher D value, lower ammonia and NDF. It was also good to see an increase in Oil-A and ash.”

“When margins are being squeezed, it’s important that farmers have tools they can rely on and this study, alongside the many on-farm trials, further reinforces the understanding that SlurryForSoil™ enhances yields, lowers the need for fertiliser and improves the carbon footprint of dairy production. It offers much more than other slurry inoculants.”

Researchers calculated that SlurryForSoil™ gave a return on investment at £23.20 for every £1 on the product in the trial.

“As well as increasing yields, SlurryForSoil™ reduced the need for fertiliser. In a commercial situation, this is extremely value, not only for the bottom line but for the carbon footprint of the farm,” says Romney.

BPI Agriculture tested two bale wrapping methods on the resulting grass in the trial, comparing traditional netwrap and film and the company’s patented Film&Film.

“Film&Film replaces netwrap with Baletite® baler film to tension the bale,” explains Stuart. “It reduces oxygen ingress and adds additional layers of protection around the mantle of the bale, and, in previous trials, it’s been proven to retain more dry matter.

“With longer lengths reducing the number of reel changes, convenient easy-to-remove PE sleeve packing rather than bulky boxes and no netwrap to wrestle with – the films peel away at opening – Film&Film is more cost-efficient and user-friendly in comparison with traditional netwrap.”

The trial at Duchy College reinforce BPI Agriculture’s findings that Film&Film does improve dry matter in comparison with net and film.

“Taking the trial beyond forage quality and into silage making was a logical next step so we were delighted that BPI Agriculture wanted to join us and extend the scope of the research,” said Romney. “We are planning further trials this year and hope to have further evidence of the results we are seeing on farm.”